|

Wolwa Group Construction Machinery Co., Ltd

|

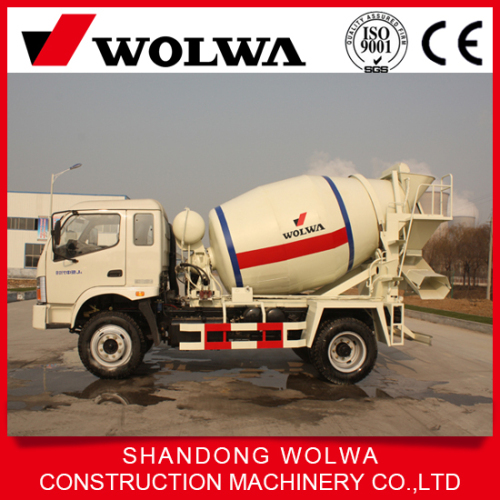

4 CBM of concrete mixer truck

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Concrete mixing truck is composed of automobile chassis and specialized concrete mixing device.

Product Name: 4 CBM of concrete mixer truck Engine Model: YC4D130-41

Chassis Type: Fukuda BJ1143VJPFA-1 Engine type: forced circulation cooling

The total mass: (kg) 13570 Engine Displacement: 4200

Vehicle size: 6460 * 2250 * 3300 Engine power: (kw) 96

V * B * H (mm)

Max. Standard transfer rate: (r / min) 3200

Wheelbase: (mm) 3400 Drum geometric volume: (m³) 6.3

Front axle: (mm) 1230 Max. mixing volume: (m³) 4

Rear overhang: (mm) 1830 Feed rate: (m³) ≥ 0.5

Maximum grade: 25 Feeding speed: (m³) ≥ 0.8

Maximum speed: (km / h) ≤ 83 Maximum speed: (r / min) 6-15

Minimum turning diameter: (m) ≤ 15 Drum inclination: (°) 16

Clutch: Twin-plate dry mix bucket often engages max. diameter: (mm) ф1900

Transmission Type: shaft drive gear: HJ200.43

Drive mode: rear-wheel drive hydraulic pumps: the right to spend 40 gear pump

Steering Type: hydraulic power hydraulic motors: Orbit Motors

Brake: breathe brake tank capacity: (L) 180

Parking brake: air brake Brake Water supply: water supply pressure

Tire :825-20

▉ Matching names have power systems: Matching Yuchai 4108 full-power engine, fuel economy, powerful, easy maintenance; under the brand name multi-file variables box, gear distribution is reasonable, the premise of improving vehicle grade ability lower actual fuel consumption;

▉ Selection of well-known components: the use of domestic Shijiazhuang Branch wing reducer, Ruianshengjie pumps, Zhenjiang strong motor;

▉ Effective solution to the overflow problem climbing: the largest hopper design, easier to fill concrete hopper unique seal design. Climbing solve the overflow problem.

▉ stirred tank design professionals: mixing tank design professionals: a large volume mixing tank design, it has a large loading space and mixing space, slender body effectively lower center of gravity, centrifugal force is small, and there is good side stability.

▉ wear good parts: the rear end of the discharge chute is covered with highly wear-resistant materials, greatly improve the wear resistance and service life, mixing blades using argon gas tank and automatic welding technology, resistant materials mixing tank and blade use life expectancy more than doubled.

▉ Rinse water convenient: Quad waterway design and tank flushing, water tank, feed inlet hopper cleaning easier.

▉ Convenient operation: manipulate the structure set up on both sides of the cab, making it easier loading unloading operation is particularly suitable for wet and muddy pavement.

▉ Reasonable access to material system design: the use of flow lines and out of the feeding system designed to ensure smooth access to materials, no leakage. Key parts of the additional reinforcement plate enhance the wear resistance, with a locking mechanism, so that the discharge chute can be fixed in place.

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

-

6 Ton Cable Tension Stringing Equipments with German Rexroth Hydraulic pumpSA-YQ60 SA-YQ90 SA-YZ30A SA-YZ2X35